The concept of managing cross contamination is a foundation principle in an effective food safety management system. Chemical products can cause cross contamination if not managed correctly in a food facility. The reality is that not all chemicals can be completely excluded from a food facility. Cleaning chemicals and other industrial chemicals such lubricants and solvents are essential to equipment maintenance and processing activities.

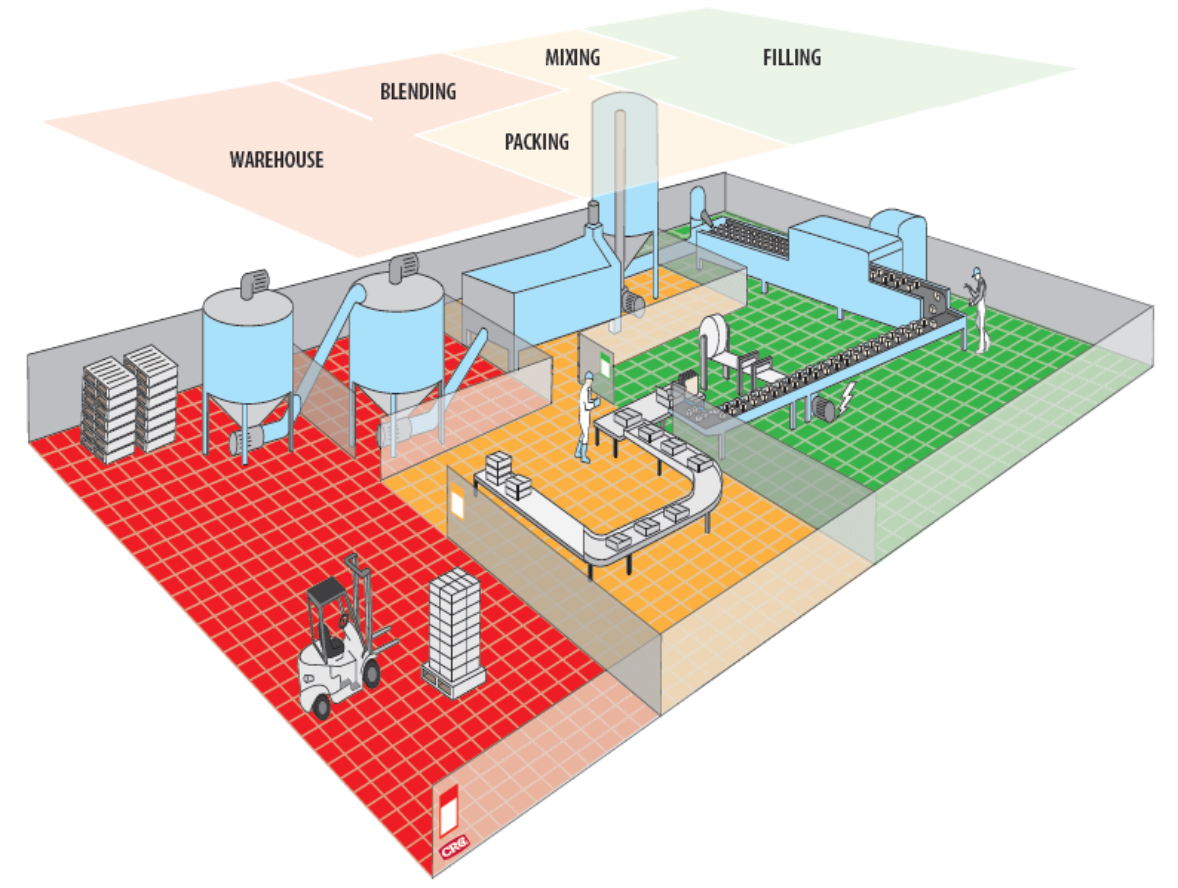

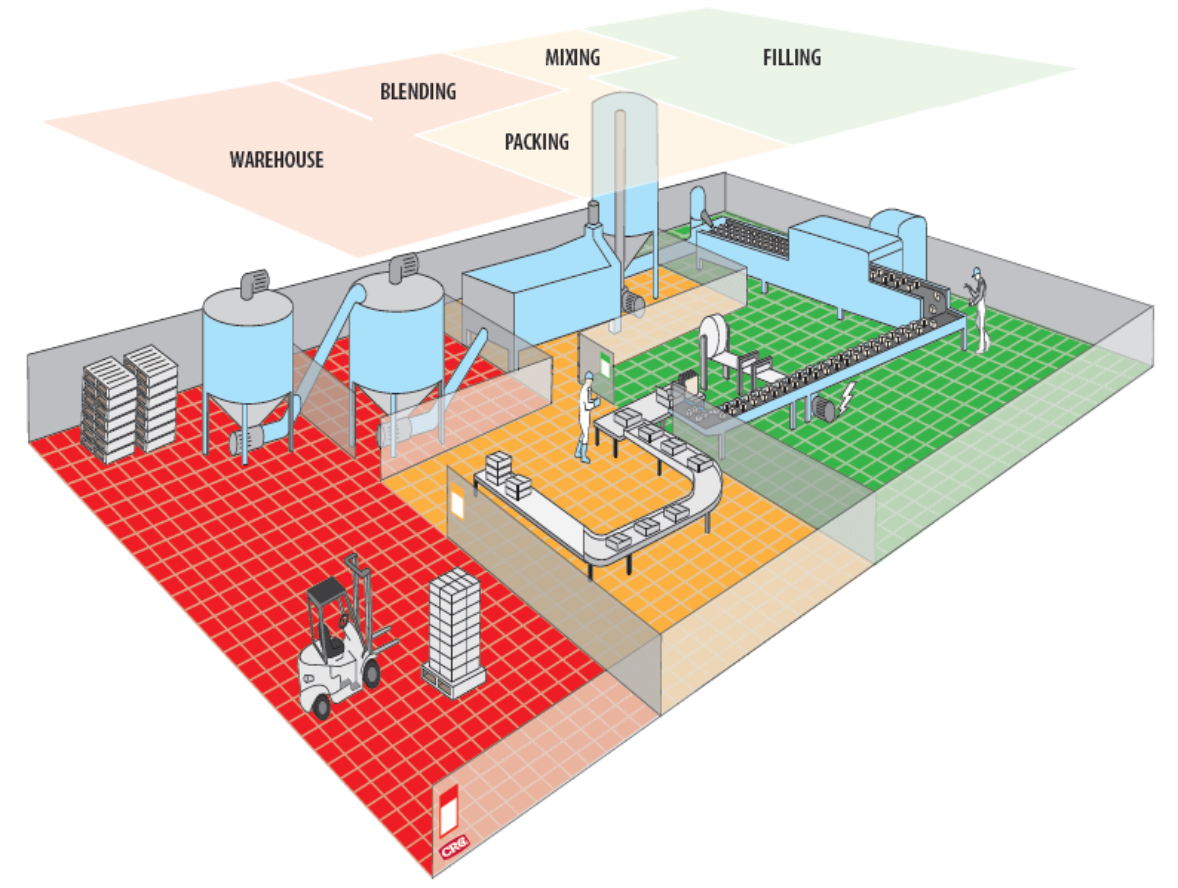

Applying zoning principles is often used for management of microbiological hazards. The definition of zoning is “the division of areas of the facility based upon the barriers, cleaning procedures, employee practices and control of movement of people, equipment and materials necessary to protect products from potential hazards originating from the manufacturing environment and its surroundings”.

Usually a hazard assessment determines potential contamination sources, susceptibility of the product and control measures suitable for these areas. The facility is then designed and constructed to separate areas where high-risk foods are processed, exposed or stored from areas where lower-risk foods and raw foods are processed, exposed or stored, and from utility areas such as equipment washing areas, microbiological laboratories, maintenance areas, waste areas, offices, and toilet facilities.

Based on the assessment, the facility is divided into areas or zones with different allowable processing steps, different hygiene rules and/or procedures for persons who are allowed entry, and/or different levels of cleanliness. Generally, the more sensitive the product or the consumer, the more important it is to separate the facility into different hygiene areas. Each manufacturing operation requires an appropriate environmental cleanliness level in order to minimize risks of contamination. Buffer zones including hand and boot wash areas, change stations and other physical (or other) barriers are often placed between the basic GMP areas to the high hygiene areas.

These zoning principles can also be used for chemical hazards. Industrial chemicals should be classified according to their use in relation to food processing equipment and the potential for direct food contact. There is a lot of focus placed on industrial lubricants but it is important to ensure that these controls also extend to Protection and Corrosion Inhibitors, Precision Cleaners, Industrial Degreasers and Cleaners that can also be a source of contamination.

Given that industrial chemicals are not intended to be consumed, their safety is related to the potential exposure to food. Terms like “food grade” are bandied about but are less well understood. A well recognized classification system distinguishes products in the following way:

H1 Acceptable as a lubricant with incidental food contact for use in and around food processing areas. Such compounds may be used on food processing equipment as a protective anti-rust film, as a release agent on gaskets or seals of tank closures, and as a lubricant for machine parts and equipment in locations in which there is a potential exposure of the lubricated part to food.

H2 Acceptable as a lubricant where there is no possibility of food contact in and around food processing areas. Such compounds may be used as lubricants, release agents, or anti-rust films on equipment and machine parts in locations in which there is no possibility of the lubricant or lubricated part contacting edible products.

3H Acceptable as a lubricant with incidental food contact for use in and around food processing areas. Such compounds may be used on food processing equipment as a protective anti-rust film, as a release agent on gaskets or seals of tank closures, and as a lubricant for machine parts and equipment in locations in which there is a potential exposure of the lubricated part to food. These products will have direct food contact.

The facility is then zoned according to risk of food/drink contamination. Green zones are where only the “safest” products are authorized such as 3H or H1, whereas amber and red zones have decreasing product controls such as H2. The diagram below indicates how the zoning would take place to ensure no accidental contamination can take place. All industrial chemicals in the zoned area would be the same classification. Rationalising the number of type of chemicals would also greatly assist the maintenance team in providing the appropriate food safety support in a practical easy-to-implement way.

Using classified and registered products verified by credible third party agencies in the Zoned Areas is best practice that reduces contamination risk. Registered non Food compound products were assessed, classified and their production facilities are inspected and audited. These products have supporting documents such Product Data Specs, Safety Data Specs (SDS), Certificates (Eg COA’s) Registration Letters as well as batch controls and traceability to provide you with the assurance you need.

Image courtesy of CRC industries

Download Plant_Zone.pdf

References

https://www.michigan.gov/documents/mdard/Zoning_in_processing_facilities_375003_7.pdf

About CRC Industries

Download CRC_FG_H1.pdf