The role of behaviour and the use of coaching to influence a safe and productive process that facilitates compliance were tested in a comprehensive study. The results show that the approach works. Within the last few years, a U.S. study and a global survey have also provided data on both as a means for attaining compliance.

Research study investigates how to change worker behaviour

In 2012 and 2013, Robert Meyer, a food industry expert for more than 40 years, developed a study to examine whether a methodology could be established to sustainably influence and change the behavior of front-line food production workers. Specifically, the study concentrated on the use of supervisory coaching that could drive employee performance to sustain food safety practices. Meyer conducted the study at four U.S. food production plants in the Midwest, South, and West Coast. Production processes that required improvement were identified at each location, as were the standards for measuring effective job performance. Each one of those standards was sequenced into process steps that were then broken down into a sequence of effective behaviors. Finally, supervisors were required to conduct corrective observations through the use of detailed checklists that contained the steps and actions necessary for compliance. The supervisors immediately initiated corrective actions when they discovered non-compliance activity.

The results of the study

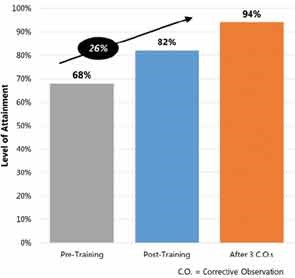

Compliance levels were measured in three steps of the study at each of the facilities: pre-training, post-training, and after corrective observations. The statistics are quite revealing:

• The average pre-training compliance level was only 68 percent, certainly far below what should be considered acceptable;

• Post-training compliance increased to 82 percent—a higher figure, but one that still leaves room for improvement; and

• After three corrective observations, the compliance rate jumped to 94 percent on average for the participating facilities.

One can safely conclude based on the study’s findings that behavior can be positively influenced to achieve safe food production. The same is true of increased productivity—an improvement noted by management at each of the four locations. Most of all, the findings from Meyer’s study indicate that behavior qualifies as a leading indicator of a company’s compliance.

Food industry expert Robert Meyer’s study chart showing improved compliance after coaching and corrective observations.

But can behavior, or anything else for that matter, be considered a leading indicator? Yes, according to a February 2014 article in EHS Today, a publication covering environmental, health, and safety issues. The article reported on a Carnegie Mellon University study determining that “75 percent in the variation in the frequency of safety incidents can be explained by the information derived from safety inspections and observations.” Author Griffin Schultz notes that based on the study, employee behavior “can provide information about both the direct and indirect causes of future safety incidents.” Schultz’s conclusion: Safety leading indicators can be determined through inspections and observations. It’s a finding that can and should be applied to observations of employee behavior in critical food safety and quality activities.

Coaching Through Technology

Management may be reluctant to get supervisors involved in coaching for several reasons. It can be time-consuming and work-intensive due to the heavy volume of record keeping that coaching necessitates. Then there is the question whether supervisors have been adequately trained to be coaches. How do they know specific questions to ask, let alone act upon? Leave it to today’s technology to provide an answer. One example is a tablet-based app developed to provide supervisors with customized templates enabling them to ask the right questions and conduct corrective observations. All the data is instantaneously entered in the employee’s file, saving supervisors considerable time and paperwork required for manual data entry.

Leading indicators are important because they represent meaningful barometers of each company’s current food safety compliance status. Quality assurance and training officers should consider routine employee observations and coaching as a food safety leading indicator program—a vital step for keeping product, workers, and consumers safe.

Article reproduced with permission from Food Quality & Safety:

http://www.foodqualityandsafety.com/article/coaching-employee-behaviors/

Author: Laura Dunn Nelson

Article edited by Linda Jackson

This article was reproduced with permission the of Food Quality & Safety and the original article can be viewed here: https://www.foodqualityandsafety.com/

Editor’s note:

Planned job observations is a term you may have come across in health and safety systems. This research suggests that this is an essential tool to support all classroom training. Look out for our next articles on how to conduct a planned job observation.